Research & Recent Developments

April 15, 2015

Superpave Gyratory Compactor. (Enlarge)

The MARC researchers introduced the advanced current state of practice in the area of cold bitumen applications, including cold mix asphalt (CMA), slurry seal, micro-surfacing, and chip seal, by providing the development of performance-based test methods and simplified mixture design procedures. An emulsion testing framework that captures properties related to critical distresses observed for surface treatments was proposed. In addition, a performance-based mix design procedure and volumetric analysis method was developed for CMA. Regarding slurry seal and micro-surfacing, a modified mixture design framework built on existing ISSA/ASTM guidelines was also developed, and verified with field mixture design. Moreover, a new sample preparation, testing and analysis procedure for chip seals that allow for the effects of existing pavement substrate, traffic load, traffic volume, and temperature on bleeding to be evaluated using the Loaded Wheel Test (LWT) device based on the selected mix design was investigated.

December 31, 2014

Preparation of Asphalt Mastic. (Enlarge)

The MARC researchers have made significant progress in studying the long term aging properties of asphalt binders in the presence of mineral aggregates. As asphalts binders are used in conjunction with mineral aggregates in pavements and roofing, possible interaction between the binder phase and the mineral fillers and aggregates can influence the aging behavior of the material. The MARC researchers found that the main cause of interaction with the filler in mastics after the aging process is the irreversible adsorption of asphaltic polar fraction (i.e., asphaltenes) by the surface of the mineral filler, thus changing the asphalt molecular size distribution during oxidation.

August 31, 2014

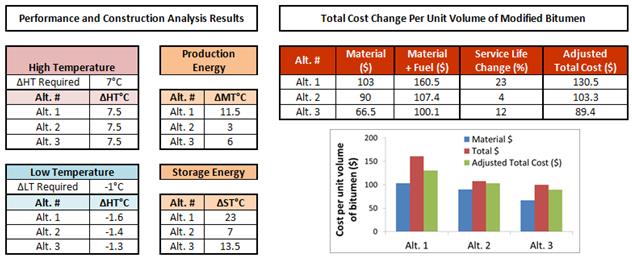

Example of results and final output level of the spreadsheet. (Enlarge)

To make a proper selection and comparison of modification techniques, MARC researchers evaluated the effect of different modification techniques including cross-linked elastomers, terpolymers, plastomeric modifiers, acids, and hybrid modification combining the aforementioned modifiers to develop a user-friendly modification selection methodology that includes energy and cost analysis to facilitate preliminary comparison of various modifier alternatives for use by contractors and designers. Furthermore, oil modifiers and extenders were investigated as possible modification techniques to effectively enhance low temperature properties. Modifier performance was evaluated using standard PG and damage resistance tests such as the Multiple Stress Creep and Recovery (MSCR), the Linear Amplitude Sweep (LAS), and the Single Edged Notched Bending test (BBR-SENB). Compositional properties for the oils were evaluated using Gel-Permeation Chromatography (GPC) and Differential Scanning Calorimetry (DSC).

April 30, 2014

BBS Test apparatus. (Enlarge)

MARC researchers recently introduced the Binder Bond Strength (BBS) test to evaluate the moisture susceptibility of asphalt-aggregate system. Bond strength values from BBS testing compared well with the work of cohesion and work of debonding estimated from surface energy measurements of binders and aggregates. A comparison between BBS results and mixture testing found that the BBS relates well to mixture performance methods and ranks materials similarly under wet conditions. Applications of the BBS test to evaluate moisture damage potential in WMA, the bond strength of mastics, and emulsion curing and residue properties were also investigated. The BBS is proved to be a viable and practical method to directly measure bond strength in dry and moisture conditions. More details about the BBS test procedure and AASHTO standard draft can be found here

.December 31, 2013

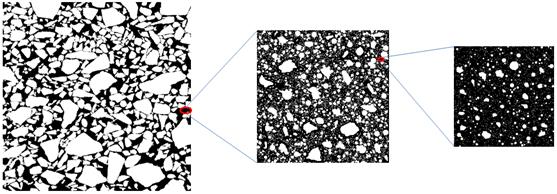

Multiscale analysis scheme (mixture scale-mortar scale-mastic scale). (Enlarge)

To help achieve a better understanding of the rutting mechanism and refine binder testing conditions to better represent pavement conditions, MARC researchers utilized an easy-to-use software (iPas2) for internal characterization of the aggregate structure, which uses 2-dimensional images simply derived from table-top scanning of cut surfaces of asphalt mixtures in the laboratory, to develop aggregate structural indices and uncover the role of modifiers in controlling the packing of aggregates and the effect aggregate structure during compaction and loading. Using this software as input, a micromechanical multiscale finite element model of asphalt mixture undergoing cyclic loading and permanent deformation was also developed and used to assess the effect of aggregate structure, gradation, and binder elasticity on the stress and strain distribution in the different mixture phases during repeated loading and deformation. These results were used to assess the effect of different modification response types on the rutting mechanisms, as well as develop a modified procedure for the MSCR test including added number of cycles and a higher and more representative stress level.

June 30, 2013

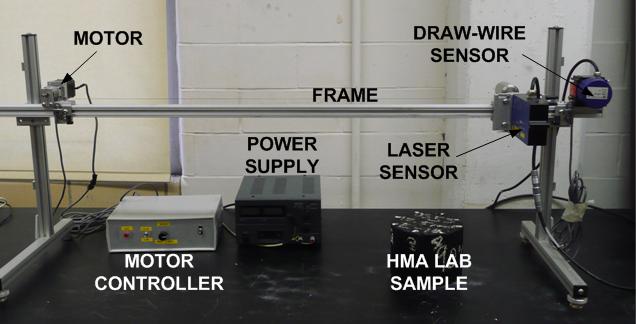

Stationary Linear Profiler (SLP). (Enlarge)

Pavement surface texture affects functional characteristics related to skid resistance and noise generation of HMA. MARC researchers has investigated the applicability of laser profiling systems for measuring surface texture of laboratory and field samples, and considered appropriate applications. Results from the research indicate that stationary laser profiling (SLP) systems can capture macro-texture and micro-texture properties of laboratory and field samples, suggesting that a comprehensive friction characterization of asphalt mixture surfaces can be obtained using laboratory test methods and texture spectral analysis (TSA) techniques. Furthermore, samples prepared using standard laboratory compaction techniques can be used to estimate field surface texture, resulting in a method that is attractive for rapid deployment. With this system, it is believed that asphalt mixture designers will have an improved tool by which to estimate pavement surface texture and the resulting frictional and acoustic properties while improving pavement sustainability.

August 1, 2012

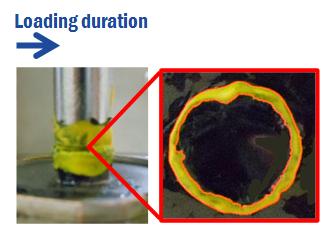

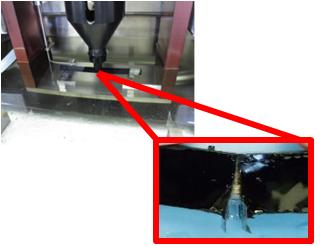

Crack propagation in fatigue testing in DSR. (Enlarge)

MARC researchers have made significant progress in characterizing asphalt binder fatigue by means of the Dynamic Shear Rheometer (DSR)-based Linear Amplitude Sweep (LAS) Test. Recent interpretation of the LAS test using image analysis shows promise in creating a "fatigue cracking resistance master curve" capable of predicting fatigue resistance at commonly encountered field conditions (i.e., temperature and loading rate). The LAS standard developed by MARC has been recently approved by AASHTO (TP101-12-UL).

MARC has joined North Carolina State University's research team on the NCHRP 09-50 project, entitled “Performance-Related Specifications for Asphaltic Binders Used in Preservation Surface Treatments.”

July 7, 2011

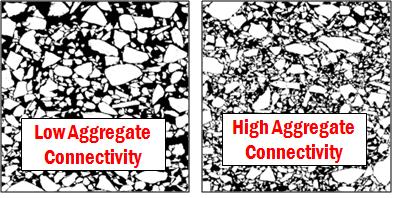

Measuring aggregate connectivity with iPas. (Enlarge)

MARC researchers played an integral role in developing and refining the Image Processing and Analysis System (iPas) software, currently in its second version. The iPas software has been successfully used to characterize the internal structure of asphalt mixtures, leading to a greater understanding of the mechanisms governing mixture compaction and performance.

From two-dimensional scanned images of an asphalt mixture, iPas estimates: number of contact zones, total contact length, and contact orientation, among other parameters.

March 31, 2010

Measuring Binder Fracture in a Modified BBR. (Enlarge)

MARC has made significant advancements in characterizing binder thermal cracking resistance by modifying the BBR device to conduct fracture testing. A Single-Edge Notched Bending Test based on a modification of the standard BBR device (BBR-SENB) has been developed and used to measure fracture properties of asphalt binders at low temperatures. The modified BBR allows to measure the force and deformation of a notched BBR sample in a displacement controlled mode, from which failure energy and strain tolerance can be estimated.

The BBR-SENB test is a good compliment to the BBR as it can measure damage resistance behavior and strain tolerance of binders at low temperatures. Experimental studies using the BBR-SENB as part of Pooled Fund Study Phase II on Low Temp Cracking and the Asphalt Research Consortium (ARC) show that fracture deformation and failure energy are good indicators of low temperature performance of asphalt binders.

September 4, 2009

This spring, UW-Madison formally approved the establishment of the Modified Asphalt Research Center. Among MARC's next steps will be to hold discussion forums with faculty members and representatives of the modified asphalt community (including several WHRP members) to define and prioritize the most critical research needs for the center. As MARC researchers move forward with these plans, they will address two driving forces in the development and deployment of modified asphalts: environment and sustainability. As a follow-up to its white paper on the topic, MARC is focusing on these key points:

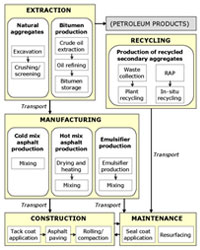

Asphalt sustainability includes the range of processes over a pavement's life cycle. (Enlarge)

- Bring attention to green construction. While the climatic and environmental impact of the transportation system as a whole has become a top-of-mind issue, discussions of climate change and energy consumption seldom focus on pavement construction methods and techniques. Sustainable pavements need to be part of the solution to minimize transportation's energy consumption, emissions and environmental impact.

- Define the metrics of sustainability. Rapid deployment of sustainable paving methods and technologies depends on understanding where the industry currently stands on key sustainability indicators. Identifying information shortages will help bring researchers, material manufacturers, contractors and road authorities to a consensus on metrics used to evaluate pavement sustainability.

- Innovate through collaboration. Existing methods to quantify pavement sustainability can be supported by data derived from a variety of sources and techniques. The scientific community should foster research, innovation and entrepreneurship in difficult economic times through international collaboration.

In support of these and related issues, MARC research is focused on identifying, testing and validating alternative pavement technologies that show promise in reducing energy consumption. Initial efforts have modeled energy consumption in manufacturing processes and investigated quantitative life-cycle analysis tools for assessing pavement sustainability. Upcoming research efforts will investigate performance characteristics and behaviors of low-energy asphalt mixes.

May 26, 2009

The MARC research team released a white paper addressing the potential for asphalt pavements to become a sustainable transportation infrastructure solution. Authored by Timothy Miller and professor Hussain Bahia, the paper “Sustainable Asphalt Pavements: Technologies, Knowledge Gaps and Opportunities (PDF, 901 kB)” addresses challenges in defining and measuring asphalt pavement sustainability; highlights available tools and models; and discusses next steps to further develop knowledge for the asphalt paving industry in the areas of energy consumption, emissions and environmental impacts.

BASF's eco-efficiency spider graph compares six different factors related to sustainability. MARC is conducting research across these areas. (Enlarge) (Image adapted from BASF)

One of the tools that MARC is using is BASF's eco-efficiency model. In this approach, a spider graph (shown at right) is used to compare different technologies in six different aspects of sustainability. MARC projects address several of these areas:

- Energy consumption. MARC is conducting research on reduced-energy asphalt mixtures, such as warm-mix asphalt and asphalt emulsion technologies

- Resource consumption. MARC research is helping define the contribution of recycled asphalt pavement to pavement performance; the goal is optimizing RAP use and minimizing consumption of virgin resources.

- Risk potential. Increased pavement life helps lower investment risk. By characterizing asphalt material properties, MARC research seeks to improve pavement performance and extend service life.

- Emissions. To fully determine the benefits of using reduced-temperature asphalts, MARC is studying the emissions that result from heating asphalt materials.

MARC is currently seeking input and feedback on this white paper from the asphalt community.

February 6, 2009

Investigators at UW-Madison's Modified Asphalt Research Center made significant progress over the last several months on research related to skid resistance, pavement friction and noise. Advances in this area will help make asphalt pavements safer and quieter, a shared concern of the WHRP Flex TOC.

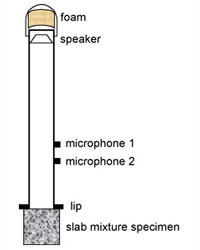

The waveguide device is a carefully configured system that includes a speaker and microphones in a PVC pipe.

- Texture Evaluation and Prediction. MARC researchers worked on laboratory procedures and prediction models for the evaluation of macro- and microtextures of asphalt pavements. Results will help form a mixture design methodology that will address not only pavement strength and durability but also traffic safety, motorist comfort and reduced pavement-tire noise.

- Measuring Sound Dissipation. The team at UW-Madison has been developing a sound absorption device to measure a pavement's ability to dissipate sound energy, similar to other devices employed at the National Center for Asphalt Technology. Open graded friction courses and stone matrix asphalt have the ability to absorb the sound resulting from pavement-tire interaction, and MARC's waveguide device will be an important tool in measuring the energy absorbed or reflected by these pavements.

- Field Testing Devices in the Lab. MARC researchers are evaluating the potential for field testing devices in obtaining information about the textural and frictional characteristics of mix designs before they reach the field. As part of an FHWA equipment loan program, UW-Madison is evaluating both a Circular Texture Meter and a Dynamic Friction Tester.

October 29, 2008

Researchers at UW-Madison's Modified Asphalt Research Center continue to address critical needs related to modified asphalts. These advances have generated significant interest in recent months:

The Wirtgen WLB10 foaming apparatus set up in the UW-Madison Asphalt Laboratory.

- Recycled Asphalt Pavements. Asphalt pavements must be recycled with care because the properties of the asphalt binder change with age. MARC researchers have developed a protocol to estimate the low-temperature rheological properties of binders in the RAP without the damaging effects of solvent extractions. The results so far are encouraging: The new procedure captures the effect of aged properties of asphalt binder in the RAP and can also estimate the low temperature PG grade of the blended binder.

- Foamed Asphalt. Foamed asphalt is a relatively new process in the United States by which moisture is injected into hot paving-grade asphalt binder, giving the asphalt a low-viscosity, foam-like consistency suitable for coating aggregates at lower temperatures. Foamed asphalt has several potential benefits, including reduced energy requirements due to lower production temperatures and as a method to mix asphalt with cold and damp aggregates for applications in partial and full depth recycling projects.

MARC researchers recently acquired a specialized device for foaming asphalt in the lab, the Wirtgen WLB10. Professor Kim Jenkins and student Andre Greyling, both from the University of Stellenbosch, South Africa, recently visited UW-Madison to shared their experience with this equipment. They will collaborate with UW-Madison on an ongoing basis on cold mix asphalt emulsion applications.